1 Join

the mesh objects.

Conceptually, this command gets all the triangles

into one bag, but it doesn't glue the edges together. (The situation is

similar to having surfaces that all fit together but have not been joined

into a solid.)

2) Weld

the new mesh object.

3) At

the Angle tolerance prompt type

180.

An angle tolerance of 180 tells the Weld

command to glue adjacent triangle points together no matter what.

4) UnifyMeshNormals.

This changes all the triangles so they

are oriented the same way, that is, if two triangles share an edge, then

they have the same idea of up.

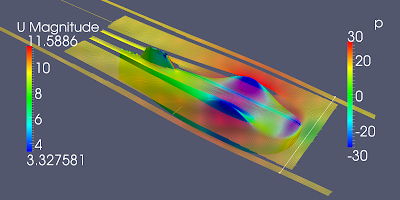

It could be that using a watertight stl improves the mesh quality but I found some holes at the bottom... (You have to click on the picture to enlarge or look at the slice) Rhino reported it changed the normals of a quite lot of cells...

It could be that using a watertight stl improves the mesh quality but I found some holes at the bottom... (You have to click on the picture to enlarge or look at the slice) Rhino reported it changed the normals of a quite lot of cells...

|

| Looks like a perfect mesh: no bumps or holes |

|

| The trailing edge is pretty sharp |

|

| Oops holes ! |

|

| A slice through the bumpy zone |

is the kinematic viscosity

is the kinematic viscosity is the distance downstream from the start of the boundary layer

is the distance downstream from the start of the boundary layer is the Reynolds Number

is the Reynolds Number is the density

is the density is the freestream velocity

is the freestream velocity is the dynamic viscosit

is the dynamic viscosit  laminar=0.0027 m = 2.7 mm

laminar=0.0027 m = 2.7 mm